|

|

|

|

|

|

|

홈 > 제품소개 > YH-6000 홈 > 제품소개 > YH-6000 |

|

|

|

|

|

| YH-6000 |

| YH6000C MED |

|

|

|

|

|

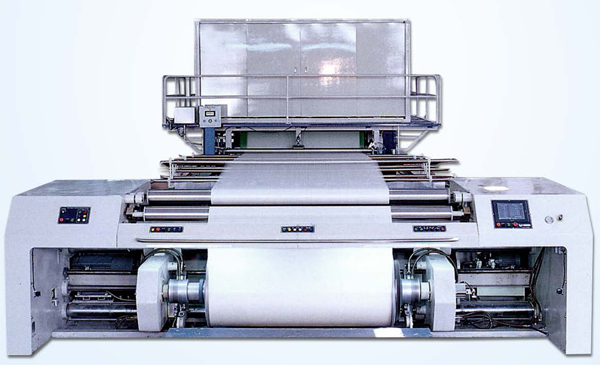

Take-up Section

This can exchange the beam of weaving machine easily and rapidly through handing automatic centering, control device and doffing switch operation. As control button and swithes are in the center of winding part, it has high efficiency in working. It also has safety device that prevents worker from being sucked into roller or beam during working. With AC Power motor, it can control wide-range winding tension, Any weaving beam can be winded, and available taper tension is from 0 to 50%

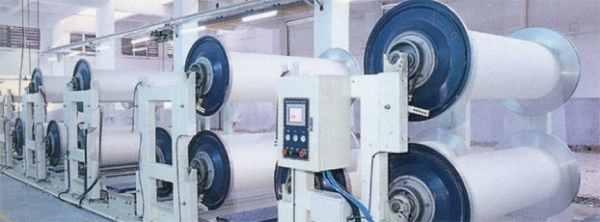

BEAM CREEL SECTION

It adopted pneumatic band braking way, and can feedback, and can prevent the droop of yarn in case of electricity failure or emergency stopping by keeping tension and stability even in case of accelerating or decelerating. Also when the diameter of beam is various, it can control tension, and it control tension with electronic tension sensing device and pneumatic diffusing device in accelerating or decelerating.

|

|

|

|

SQUEEZING SECTION

6 unique roller's structure, filtering device of adulteration and deposit in box, recycling device and size liquid mixing that make equal viscosity and attachment by flowing the size liquid from size box to cavity box cavity box make possible the sizing of so little density like no. 500 yarns that guarantee the uniformity of yarn sheet. As all rollers are located on the upper side of size liquid, the flow of size liquid in size box is smooth, so glue is decreased. Also by adopting double structured size box to prevent size liquid from being socked into the bearing of roller axis, the life of bearing becomes longer. Cavity box is jacket structure that is made of stainless steel and direct heating way by steam diffusion, and also temperature sensor and size level sensing low/high size level automatic supply device are attached.

|

|

|

|

DRYING CYLINEDR SECTION

The tention control device with an AC servo motor very accurately controls tension. It helps produce high-quality yarn beam by perventing the run-out of yarn with the automatic tension control.

Double Powder System(Opt…)

For high tension working for take up tension, installation of two powders on the beam stand of option gives tension of 5kg at the minimum up to 80kg.

|

|

|

|

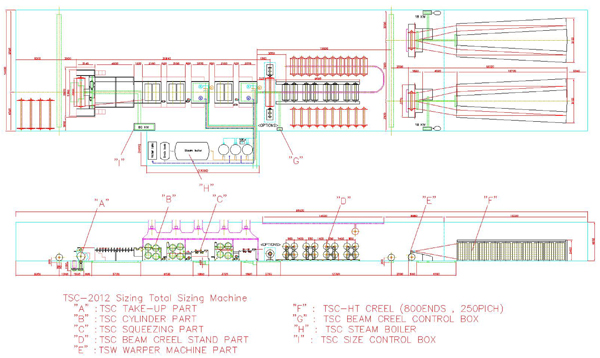

| Lay out of YHC-S2012 MED Cotton Total Sizing System |

|

|

|

|

|

|

|

|

|

|

|

|

|