| YH-1600 |

| BEAMING MACHINE |

|

|

|

|

|

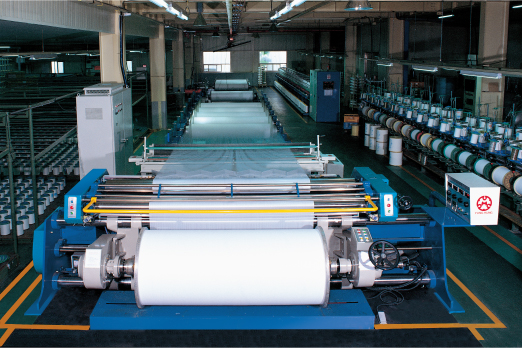

| Beamer |

비밍기 최대 속도는 200m/min, 장력은 600kg, 최대 폭은 2,200mm, 최대 룸빔 직경은 Ø 1,000까지 가능합니다.

이 기계는 정류기에 의해 조정되는 DC모터를 사용하기 때문에 속도를 자유롭게 조절할 수가 있으며 다이나믹한 브레이크 장치의 부착으로 조작이 아주 편리 합니다. |

|

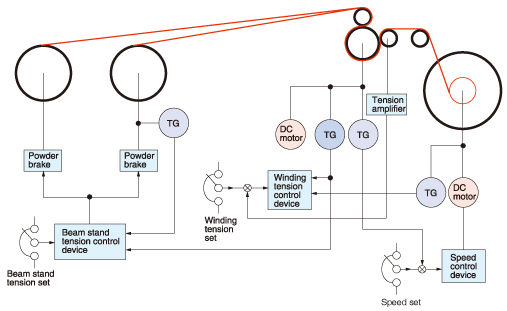

| Beam Stand |

| 빔 스탠드에 장착된 섹션 빔은 권경 변화에 따른 보정이 이루어지는 동안에 파우더 브레이크에 의해서 안정된 장력이 일정하게 유지됩니다. 전자식 권경 피드백 시스템에 의한 자동장력제어로 실의 처짐을 방지하는 장치 및 정전시 비상정지 장치 등은 운전 중이거나 가속 및 감소 시에도 일정하게 안정된 장력을 유지해 줍니다. |

|

|

|

| Leasing device |

리징장치는 비밍기의 빔 스탠드부와 권취부사이에 설치되며 와파 빔으로부터 분산되어 나오는 실을 효율적, 능률적으로 분리해 줍니다. 이장치는 무연, 유연, 및 가공사 등 사종에 관계없이 정확한 리징작업을 할 수 있는 특수한 장치 입니다.

특히 강연하물의 좌우사 구분 및 리징작업에 유용한 장치 입니다. |

|

|

|

| Speed Control System |

룸빔의 직경변화에 따라 일정한 속도를 유지하기 위한 특수한 DC모터를 사용합니다.

섹션빔의 직경변화에 따라 일정한 장력을 유지하기 위해서 파우더 브레이크시스템을 채용하고 있으며 권취장력은 테이크엎로라에 연결된 두 개의 DC모터에 의해 조절됩니다.

DC모터의 토르크에 의해 섹션빔의 직경변화에 따라 자동적으로 장력이 조절되며 테파텐션도 볼륜에 의해서 손쉽게 조절됩니다. |

|

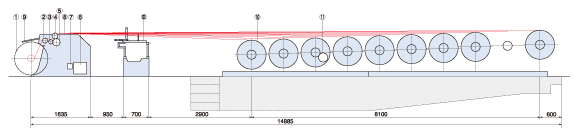

| BEAMING MACHINE DIMENSION |

|

|

|

| SPECIFICATION |

|

|

| INDEX |

SPECIFICATION |

| Nominal width |

2,200mm(Option : 2,500mm) |

| Max. yarn beaming speed |

200m/min |

| Max. tension |

600kg |

| Number of section beams on the creel |

10(Option : 12) |

| Max. number of warp end on loom beam |

14,400 |

| Max. loom beam flange diameter |

Ø1,000 |

| Dricing motor |

30kw DC motor |

| Beaming system |

Direct take-up by DC motor |

| Beaming tension control |

Automatic electric control |

| Beaming headstocks |

Ex(amdomg & sliding shaft) |

| Taper tension |

0~50kg |

| Change of speed |

Linearly by dial |

| Loom beam lifting & doffing system |

Motor & Hydraulic(Option) |

| Tensioners on beam creel |

Electromagnetic powder brakes |

| Tension indicators for individual section beams |

Can be optionally equipped |

| Operator per shift |

1 |

|

|

|

1 Loom beam

2 Measuring roller

3 Tension roller

4 Pushing roller |

5 Take-up roller

6 DC motor

7 DC motor

8 Zig-zag reed |

9 Safety bar

10 Warper beam

11 Powder brake

12 Leasing M/C |

|

|

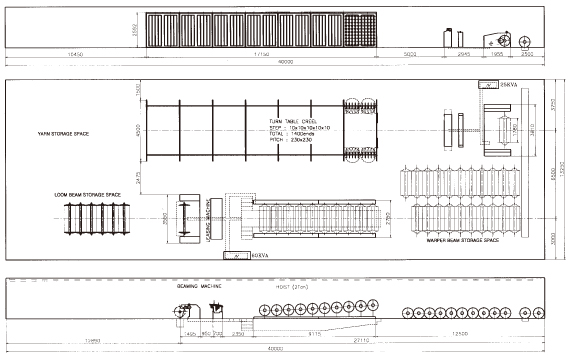

| LAY OUT OF YH-1600 DIRECT WARPER SYSTEM |

|

|